Cleaning the Material: The first step in the annealing process is to clean the material that is going to be annealed. This is done to remove any impurities or contaminants that could interfere with the annealing process.

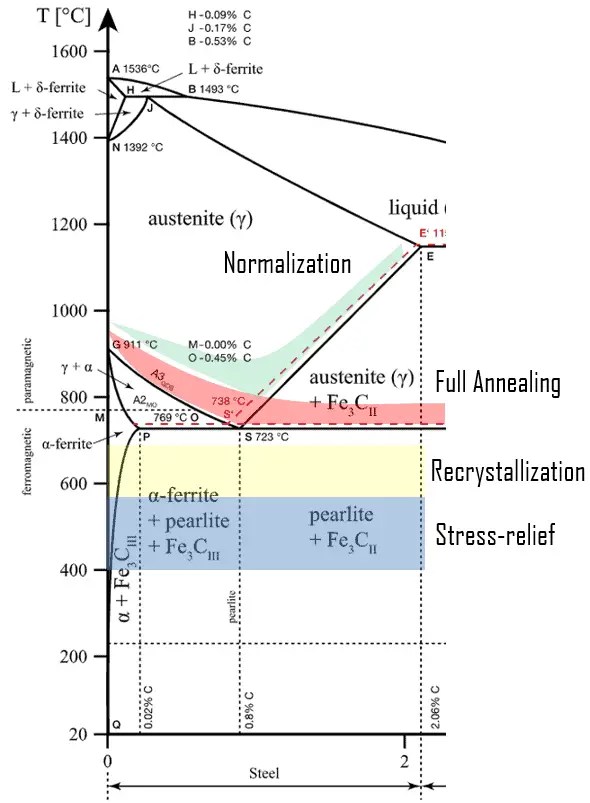

Heating: Once the material is clean, it is placed in a furnace and heated to a specific temperature. The temperature to which the material is heated depends on the type of material and the desired properties. For example, steel is typically heated to around 1,100°C (2,012°F) for annealing.

Soaking: After the material has reached the desired temperature, it is held at that temperature for a certain period of time. This is known as soaking and it allows the material to reach a uniform temperature throughout.

Cooling: Once the material has soaked for the appropriate amount of time, it is slowly cooled down. The cooling rate is important because it affects the final properties of the material. The slower the cooling rate, the more time the atoms have to rearrange themselves, which can result in a softer and more ductile material.

Quenching: Some materials, such as certain types of steel, are quenched after annealing. Quenching involves rapidly cooling the material in a liquid, such as water or oil, to increase its hardness. This is often followed by tempering, which is a heat treatment process that further improves the material’s properties.

Testing: After annealing and any subsequent treatments, the material is tested to ensure that it meets the desired specifications. This can involve testing for properties such as strength, hardness, ductility, and toughness.

Overall, the annealing process is a critical step in the manufacturing of many types of materials. By carefully controlling the heating and cooling of the material, manufacturers can produce materials with specific properties that make them suitable for a wide range of applications.